PROSEALS specializes in providing high-precision metal components, including stainless steel, brass, aluminum, carbon steel, and titanium sealing solutions.

Our customers include the automotive, oil & gas, chemical, and hydraulic industries, who rely on PROSEALS for extensive parts availability and just-in-time delivery to keep their business moving. We offer metal parts availability with tight tolerances, maximum strength and durability required for critical applications. Along with our sourcing we also offer quality inspection services and inventory management for these components to save our customers both time and money.

MACHINING CAPABILITIES:

- CNC Bar Fed Lathes

- CNC Turning Centers

- Multi Spindle Screw Machines

- Vertical Milling Centers

- Centerless Grinding

Global Supplier Network

PROSEALS works closely with an extensive network of manufacturers for precision metal components, with two locations to serve our customers in

North America and

Europe with quality products engineered to the highest standards. With facilities in

USA and

Germany, we are able to promptly provide any grade or finish of metal products, including carbon steel, titanium, stainless steel, aluminum, brass and more to our industrial customer base around the world.

METAL COMPONENTS /

STAINLESS STEEL

Stainless Steel

Stainless steel’s resistance to corrosion and staining, low maintenance and familiar lustre make it an ideal material for many applications. There are over 150 grades of stainless steel, of which fifteen are most commonly used. There are different grades and surface finishes of stainless steel to suit the environment the alloy must endure. Stainless steel is used where both the properties of steel and corrosion resistance are required.

Stainless steels are used in cast, wrought and powder metallurgy forms. Applications include wipers, brackets, tubing, springs, clamps, fasteners, sensors, gaskets, air bag assemblies, flanges, wheels, fuel tanks, and bus structurals/panels. Parts are made from austenitic stainless steels, which contain nickel, or ferritic stainless steels, with little or no nickel in less demanding applications. Some of these parts are made in stainless steel only for use in higher quality autos or where superior performance is desired.

Contact us for Stainless Steel Components availability

METAL COMPONENTS /

BRASS

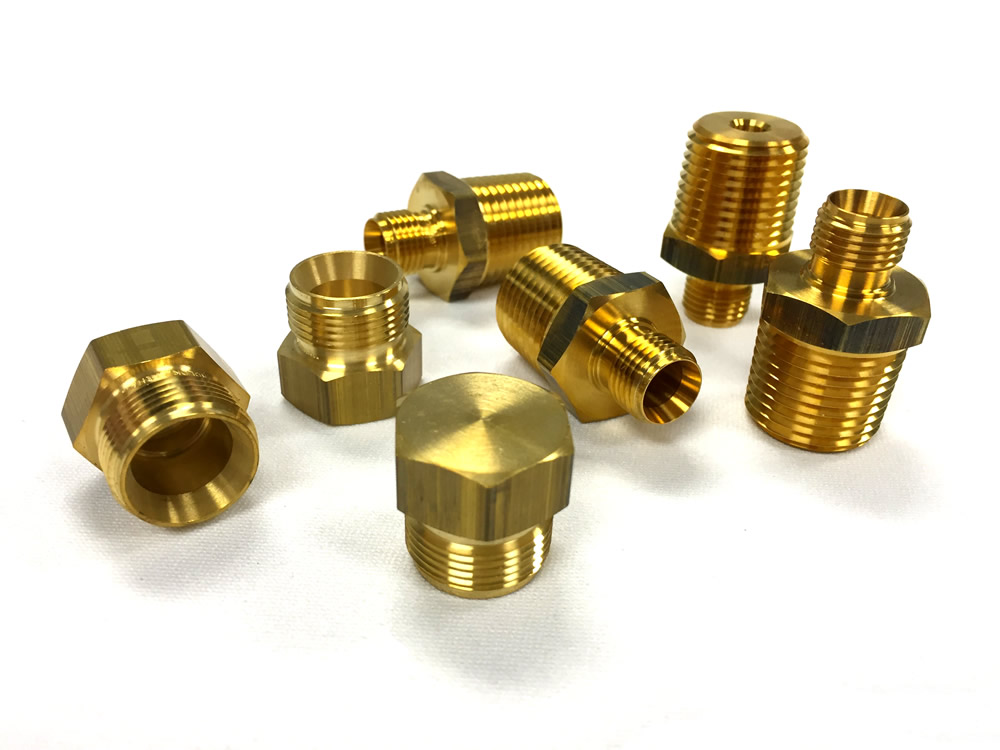

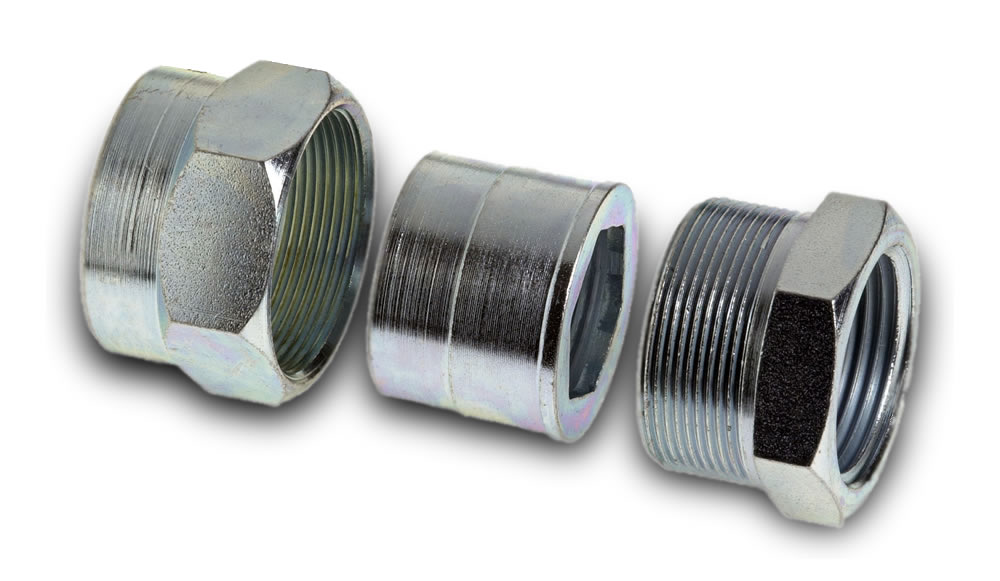

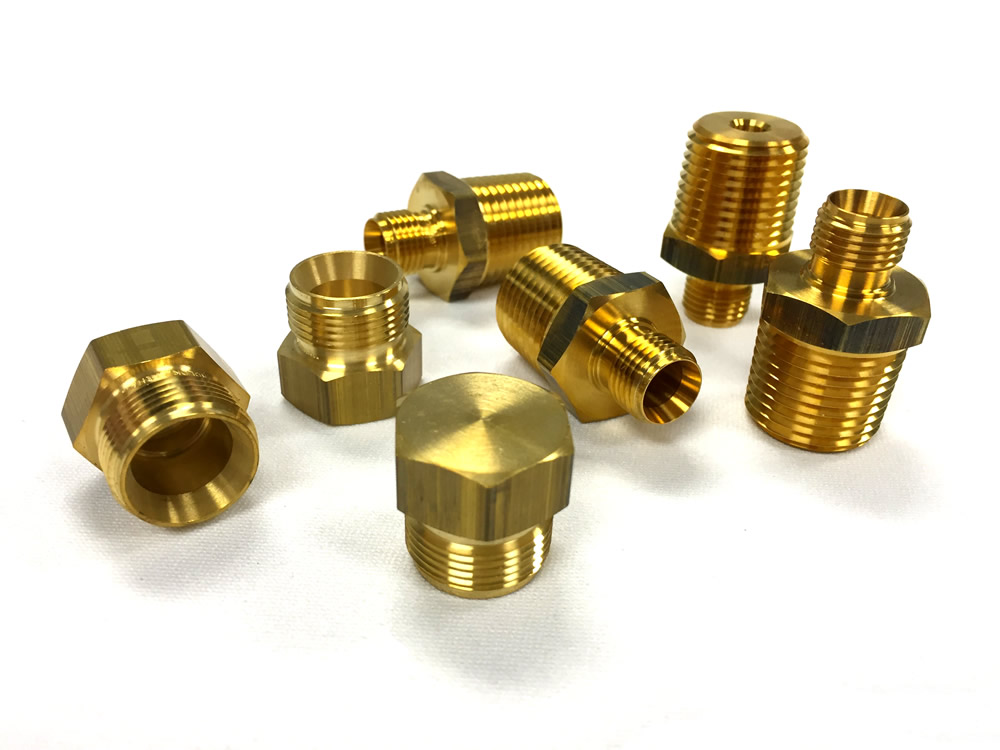

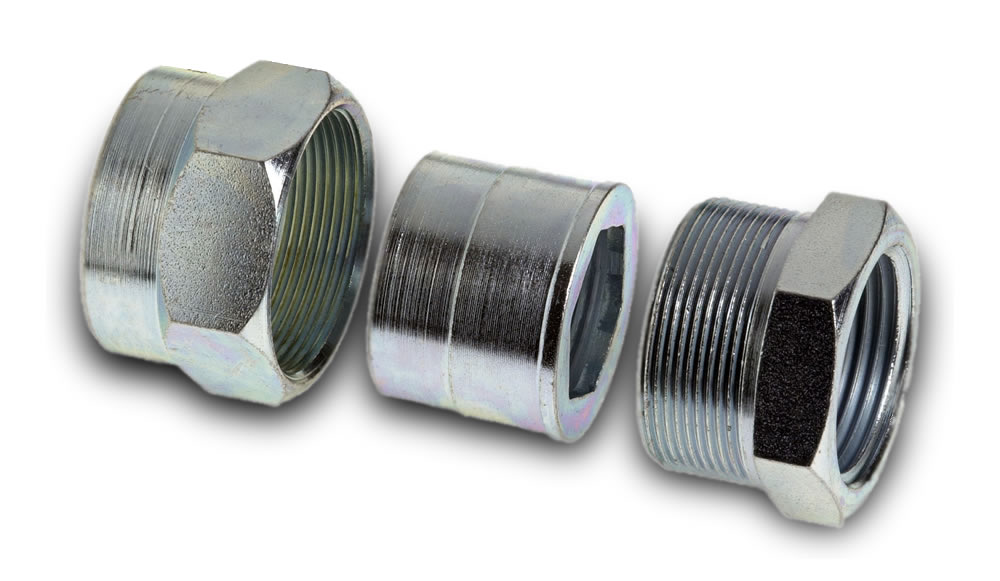

Brass

Brass is a metal alloy made of copper and zinc; the proportions of zinc and copper can be varied to create a range of brasses with varying properties. It is a substitutional alloy: atoms of the two constituents may replace each other within the same crystal structure.

Brass has higher malleability than bronze or zinc. The relatively low melting point of brass (900 to 940 °C, 1652 to 1724 °F, depending on composition) and its flow characteristics make it a relatively easy material to cast. By varying the proportions of copper and zinc, the properties of the brass can be changed, allowing hard and soft brasses. The density of brass is approximately .303 lb/cubic inch, 8.4 to 8.73 grams per cubic centimetre.

Aluminium makes brass stronger and more corrosion-resistant. Aluminium also causes a highly beneficial hard layer of aluminium oxide (Al2O3) to be formed on the surface that is thin, transparent and self-healing. Tin has a similar effect and finds its use especially in seawater applications (naval brasses). Combinations of iron, aluminium, silicon and manganese make brass wear and tear resistant.

Contact us for Brass Components availability

METAL COMPONENTS /

ALUMINUM

Aluminum

Aluminium is remarkable for the metal's low density and for its ability to resist corrosion due to the phenomenon of passivation. Structural components made from aluminium and its alloys are vital to the aerospace industry and are important in other areas of transportation and structural materials.

Aluminium is the most widely used non-ferrous metal. Global production of aluminium in 2005 was 31.9 million tonnes. It exceeded that of any other metal except iron.

Aluminium is usually alloyed – it is used as pure metal only when corrosion resistance and/or workability is more important than strength or hardness. Aluminium-based alloys abruptly increase their strength characteristics with small additions of scandium, as well as zirconium and hafnium.

Contact us for Aluminum Components availability